I Main features:

- Servo feeding, accurate cutting length tolerance

- One time cutting four pieces, high efficient

- Pull-apart method eliminates ID reduction of tube end

- Clean, chipless and burrless cutting, no need further end processing

- PLC control, high automation—auto feed, auto cut, auto unload, auto alarm.

II Main technical data

|

No. |

Item |

Data |

|

1 |

Applicable copper tube |

Coil, TP1/2 (M/M2) |

|

2 |

Copper tube diameter range |

Ф6.0~Ф20mm |

|

3 |

Copper tube wall thickness |

0.3~1.0mm |

|

4 |

Cutting length range |

40~6000mm |

|

5 |

Pay-off device |

4 |

|

6 |

Copper coil reel size |

OD: 1000~1250mm; ID: 130mm, weight: max. 280kg |

|

7 |

Cutting stations |

2x2 or (1x4)* |

|

8 |

Cutting speed |

10 cuts per minute (@L=1000mm)** |

|

9 |

Feeding speed |

Max. 0.5m/s |

|

10 |

One-time feeding stroke |

Max. 1200mm |

|

11 |

Straightness tolerance |

≤2‰ |

|

12 |

Cut-to-length tolerance |

≤0.3mm /1000mm |

|

13 |

Length difference between tubes |

≤0.5mm |

|

14 |

Tube end ID reduction ratio |

f < 20%*** |

|

15 |

Roundness of cut tubes |

Non-roundness ≤3% (diameter ≤Ф12.7mm) Non-roundness≤0.4mm(diameter>Ф12.7mm) |

|

16 |

Surface condition after cut |

No apparent scratch, drawing marks; no burrs |

|

17 |

Compressed air |

0.5-0.7MPa |

|

18 |

Total electric consumption |

6kW |

* 1- 2x2 means there are two separate driving system for cutting 2 pairs tubes in different diameter and different length; 1x4 means there is only driving system for cutting 4 tubes in same diameter and length, two different options.

** 2- When cutting length is less than 100mm, there will be no pre-stretching function.

*** 3- Tube end ID reduction ratio means:

f= (d1-d0)/d0%

f= (d1-d0)/d0%

3.1 Pay-off device: active decoiling, with clutch**

3.2 Straightening & rounding device: straightening deformation can be adjusted for different hardness copper tubes. When size changing, rounding wheel and straightening wheel will be changed.

3.3 Feeding device: driven by servo motor; Pulling and clamping dies are driven by enhanced pneumatic cylinders.

3.4 Cutting device: orbital-notching + stretching method, pneumatic driving feeding stroke of orbital blade, stable feeding and quick returning; The feeding stroke can be fine adjusted to assure same mouth shrinking rate; Equipped with lubricant spraying device for lengthening blade life.

3.5 Unloading table: covered with stainless steel, 1500mm long

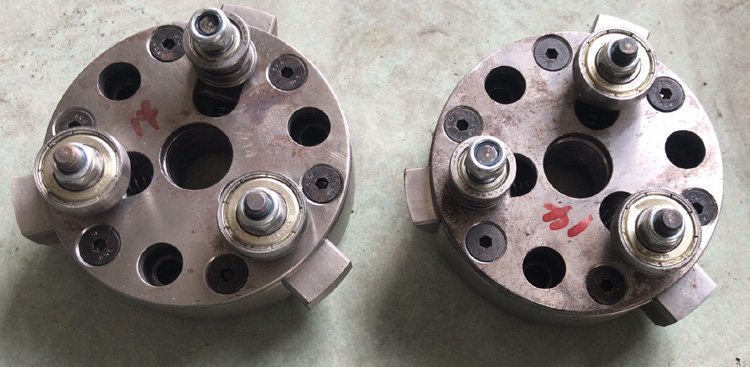

3.6 All the clamping dies are made by chrome steel, quenched HRC 50

3.7 Control system: PLC + touch screen

**Note: When copper diameter is not more than 9.52mm, simple passive pay-off device can be used.

Products

Car Radiator Machines Car AC Condenser Machines Car AC Evaporator Machines Copper Radiator Machines Intercooler Machines Oil Cooler Machines Home AC Machines Refrigerator Making Machines Copper Fitting Machines Brazing Agent Machinery Nantong Zhenhuan Trade Co., Ltd. Add: No.243,Ninghai Road, Rugao City, Jiangsu Province, China 226500