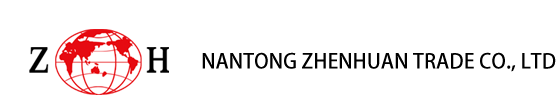

This aluminum radiator tube mill is specially designed for producing flat aluminum tube (optional header pipes) used in automobile radiators, condenser/evaporators, round & rectangular aluminum pipes and other special shape aluminum pipes.It can 100% replace those aluminum pipe welding machines from Schoeler Germany, Millmaster USA or Japan.

I Main features of aluminum radiator tube mill

- Special roller designing and adjusting technology for various aluminum pipe forming, quick roller cassette changing:

- Max. production speed 100m/min

- High quality solid state high-frequency welder, less electric consumption, smaller internal burr

- Online cut-to-length, no need secondary processing

- Special cutting device, supper high speed cutting catching the whole line speed

300~375 cuts/min @400mm length

160~200 cuts/min @750mm length

120~150 cuts/min @1000mm length

40~50 cuts/min @3000mm length

20~25 cuts/min @6000mm length

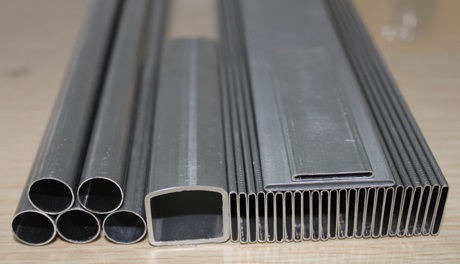

- Optional vacuum absorber for aluminum coil loading:

|aluminum radiator tube mill|aluminum radiator pipe mill| high frequency aluminum pipe welding machine| high frequency aluminum tube welding machine|

II Main technical data of aluminum radiator tube mill

|

Item |

Data |

|

Suitable material |

Pure aluminum or aluminum alloy 4343/3003/7072 or 4343/3005/7072 |

|

Applicable flat aluminum pipe size |

16~32mm x 1.5~3.0mm x 0.28~0.35mm (or customized) |

|

Applicable rectangular aluminum pipe size |

50~90mm x 8mm x 0.32~0.6mm |

|

Applicable round aluminum pipe size |

Ф8-32mm |

|

Suitable aluminum pipe length |

300~8000mm |

|

Applicable aluminum strip coil size |

Max. OD:1900mm; ID 290~310mm; max. Weight 800kg |

|

Production speed |

Max. 100m/min |

|

Cooling method for welder |

Air cooler |

|

Cooling method for rollers |

Liquid type coolant |

|

Straightness of finished pipe |

≤1mm @1000mm length |

|

Cutting end inclination |

≤0.3mm |

|

Cutting burr height |

≤0.08mm |

|

Cut-to-length precision |

≤ ±0.3mm |

|

Life of cutting blades |

More than 0.2 billion cuts |

|

Duration for changing rollers |

2~4 hours |

|

Duration for changing tube width |

≤ 15min |

|

High-frequency power |

100kVA |

|

Total electric power |

About 150kVA |

|

Total electric consumption |

About 70 kW·h |

|

Air source |

0.5-0.7MPa, 3m3/min |

|

Noise level |

≤78dB (@2m away) |

|

Pollution |

Welding smoke & dust collecting, no liquid pollution discharged |

|

Total weight |

About 15 Tons |

|

Whole line dimension |

About 26m x 4.5m x 3.5m |

III Main configuration of aluminum radiator tube mill

- PLC & HMI: Siemens from Germany

- Servo motor & driver: Yaskawa from Japan

- Contactor& circuit breaker: Schneider (Chinese joint venture)

- Pneumatic components: Airtac from Taiwan

IV More photos of aluminum radiator tube mill

|aluminum radiator tube mill|aluminum radiator pipe mill| high frequency aluminum pipe welding machine| high frequency aluminum tube welding machine|

Products

Car Radiator Machines Car AC Condenser Machines Car AC Evaporator Machines Copper Radiator Machines Intercooler Machines Oil Cooler Machines Home AC Machines Refrigerator Making Machines Copper Fitting Machines Brazing Agent Machinery Nantong Zhenhuan Trade Co., Ltd. Add: No.243,Ninghai Road, Rugao City, Jiangsu Province, China 226500