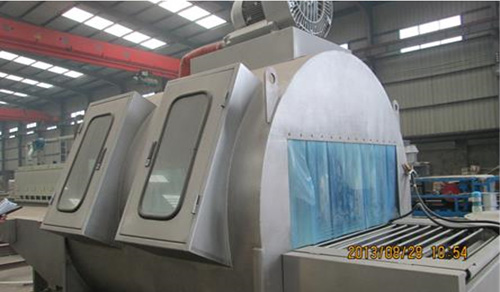

I Brief description of continuous aluminum brazing oven

Continuous aluminum brazing oven is designed for brazing various aluminum cores, such as radiator cores, condenser cores, evaporator cores, intercooler cores, oil cooler cores, hot-wind cores, etc.

The brazing oven will use non-corrosive flux (Nocolok Flux) for brazing under Nitrogen atmosphere protection.

|continuous aluminum brazing oven|continuous radiator core brazing oven|continuous aluminum brazing oven|continuous radiator core brazing oven|

II Main composition of continuous aluminum brazing oven

1) Degreasing oven or stand alone washing machine (optional)

2) Continuous flux spraying section

3) Drying oven

4) Front-curtain room of brazing section

5) Pre-heating and brazing section

6) Slag-removal room

7) Water cooling / static air cooling room

8) Rear-curtain room of brazing section

9) Compulsive air cooling room

10) Control system

11) Water & nitrogen supplying device|continuous aluminum brazing oven|continuous radiator core brazing oven|continuous aluminum brazing oven|continuous radiator core brazing oven|

III Main features of continuous aluminum brazing oven

3.1 Optional stand alone washing machine, perfect cleaning quality

3.2 Flux spraying section

- Whole body is made from stainless steel 304 and designed in reinforced structure, assuring long-life faultless serving.

- System can spray fluxes to core section and header plates accurately.

- Spraying nozzle is easily demountable.

- Round-cylinder design assures non-piling-up during fluxes collecting.

- A manual spraying section is added on exit of this spraying room, for partial increasing flux.

- Height of high-pressure fan blade is adjustable for better removing excess flux.

- One unit filter is provided in flux recycling system to avoid foreign objects damaging spraying pump.

3.3 Drying oven

- Adopting natural gas as heating source; Burner nozzles are Baltur from Italy.

- Internal surface and wind scooper are made from SS304, 1.5mm thick

- Transmitting belt is made from SS304, inverter control

- A cleaning & overhauling entrance is provided on the body.

- Equipped with heat recycling exchanger to recover exhausted heat, saving energy

3.4 Brazing oven

- Full oven is insulated by high-performance fiberglass wool, good thermal insulation. Temperature rising time (from ambient to 630°C) is only 2.5 hours. Heating consumption during brazing is less than 60% of installed power.

- Muff body is made from SS 304 and 316L, one whole plate folded, only two welding seams, very small deformation because of welding stress, very small deformation during working.

- Four sectional temperature control, high control precision (±1℃); Temperature evenness in same section is within ±3℃.

- Slag-removing room is equipped with separate Nitrogen pre-heating system which can heat nitrogen gas to 300℃. Thus also saves energy consumption.

3.5 Natural gas burning system as heating source is optional.

We can configure the most applicable continuous aluminum brazing oven according to your core size, thickness and productivity. |continuous aluminum brazing oven|continuous radiator core brazing oven|continuous aluminum brazing oven|continuous radiator core brazing oven|

Products

Car Radiator Machines Car AC Condenser Machines Car AC Evaporator Machines Copper Radiator Machines Intercooler Machines Oil Cooler Machines Home AC Machines Refrigerator Making Machines Copper Fitting Machines Brazing Agent Machinery Nantong Zhenhuan Trade Co., Ltd. Add: No.243,Ninghai Road, Rugao City, Jiangsu Province, China 226500