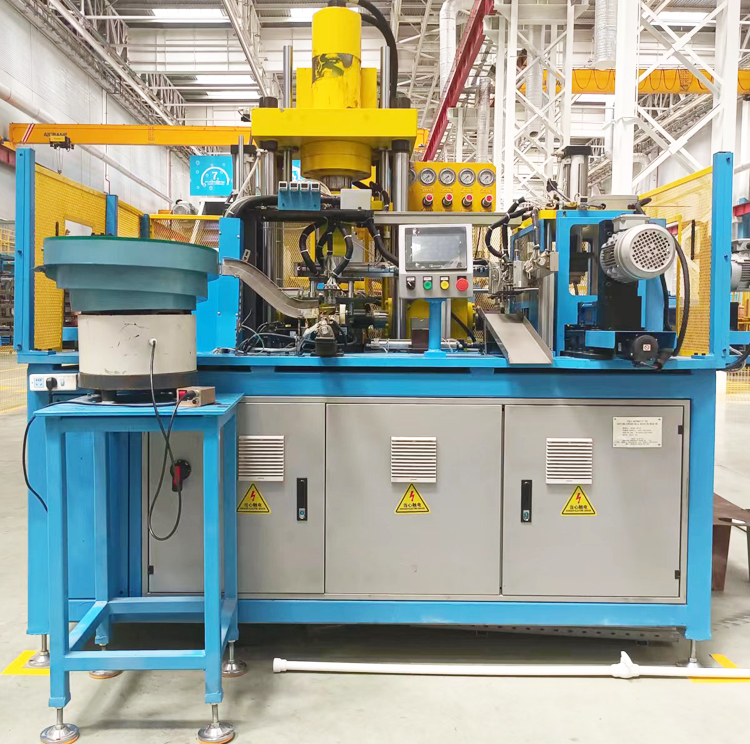

This machine is specially designed for making copper elbows min. diameter 15mm, rotating-arm for multi-station design, combing push-bending, two-end expanding and two-end ordering (chamfering) together.

This machine is capable for 90° elbow, or 45° elbow, or any other special degree elbow.

This machine is comprised of automatic elevator feeding device, four-station turn-table, auto unloading device, pneumatic system and PLC control system.

By changing tooling/moulds, different sizes (in same shape) elbows can be produced.

Main technical data:

Item

RDWZ24-4

RDWZ40-4

Graduated turntable

Servo drive, 4 stations

Applicable blank material

Bevelled cut tubes

Applicable copper tube diameter

Max. Φ 24mm

Max. Φ 40mm

Cycle time

6~8.0 seconds

12~20 seconds

Productivity

3600~4800 pcs per 8 hours

1440~2400 pcs per 8 hours

Tube mouth deformation ratio

Less than 3%

Servo motor power for rotating

0.4kW

0.4kW

Servo motor for end ordering

0.75kW x 2

1.1kW x 2

Hydraulic pump motor power

11kW

2 x 18.5kW

Hydraulic pressure

25MPa

Pneumatic pressure

0.5-0.7MPa

Cooling water

0.2~0.3MPa, temperature≤32ºC, flow 120L/min

|copper elbow making machine| copper elbow machine| copper elbow making machine|copper elbow machine|

When copper elbow diameter less than 15mm, making machine will be different to above 4-station, but in 3-station, say, loading/unloading, expanding and chamfering.

Blank tubes for this machine is pre-bent in 45 degree or 90 degree by a separate return tube bender:

Products

Car Radiator Machines Car AC Condenser Machines Car AC Evaporator Machines Copper Radiator Machines Intercooler Machines Oil Cooler Machines Home AC Machines Refrigerator Making Machines Copper Fitting Machines Brazing Agent Machinery Nantong Zhenhuan Trade Co., Ltd. Add: No.243,Ninghai Road, Rugao City, Jiangsu Province, China 226500