The folded tubes are produced from brazing sheet coils by a multi-step roll forming process – bringing the sheet gradually into a “B” shape. Comparing to traditional HF welded flat tubes, B-tubes have certain advantages – particularly regarding strength. The folded ends of the tube sheet are brazed inside the tube, which creates a very robust bridge between the walls. This results in higher burst pressure resistance.

And thus thinner aluminum strips can be used to decrease material cost of radiator tubes.

Further more, heat transferring result of radiator cores by folded B tubes is better than that of HF seam-welded tubes.

Tube rolling moulds are designed in quick-changeable cassette type. By changing this kind of cassette, other size aluminum tubes can be produced as well.

This machine can 100% replace those aluminum pipe mill from Schoeler Germany, Millmaster USA or Mori Japan.

Production flow:

- Aluminum strip reel loading by vacuum absorber loading device (optional)

- Aluminum strip decoiling by twin-head active decoiler

- Aluminum strip feeding by synchronization feeder with buffer

- Roll forming by 15 stations rollers, including online dimpling

- Cutting to length by non-stop high speed cutter

- Transmitting, with bad tube separating & collecting

- Auto tube stacking system (optional)

Main features of radiator folded B tube mill:

- Servo screw pump pasting brazing flux on internal surface before forming, programmable, real-time visual inspection, assuring pasting quality and further brazing quality

- Special roller designing and adjusting technology for various aluminum pipe forming

- Quick roller changing, only two workers and 60 minutes to finish size changing

- Perfect coordination between dimpling and cutting devices, margin length can be set freely

- Dual-station tube transmitting belt, capable for separately collecting good and bad tubes

- Special cutting device, supper high speed cutting catching the whole line speed, max. Cutting speed 300 tubes/min.

- Dimpling and cutting are matched ideally, margin length on tube end can be freely preset

- Equipped with safety barrier, protection cover, door switch and voice-light alarming

- Equipped with oil mist collecting device, recovering rate >85%

Main technical data of radiator folded B tube mill:

Item

Data

Suitable material

Pure aluminum or aluminum alloy 4343/3003/7072 or 4343/3005/7072

Applicable B tube size

16~32mm x 1.4~2.5mm x 0.18~0.35mm

Finished B tube outline dimension error**

≤±0.05mm

Suitable tube length

200~1200mm

Applicable aluminum strip coil size

Max. OD:1900mm; ID 290~310mm; max. Weight 500kg

Production speed

Max. 120m/min

Cut-to-length precision

≤ ±0.5mm

Life of cutting blades

More than 0.2 billion cuts

Duration for changing rollers

60 minutes (cassette changing)

Total electric power

About 25kVA

Air source

0.5-0.7MPa, 0.5m3/min

Noise level

≤75dB (@1.5m away from safety barrier)

Lubricant mist collecting rate

More than 85%

Total weight

About 4500kg

Whole line dimension

About 14.3m x 5.1m x 2.2m (including tube stacking system)

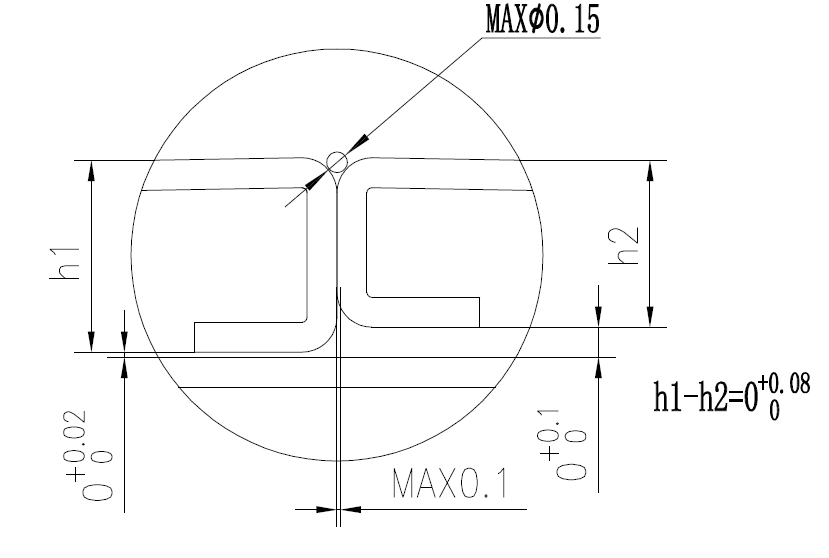

** For folded B tube quality, there are below important parameters to be promised:

- Diameter of Delta area is not more than 0.15mm.

- Two legs height difference is not more than +0.08mm.

Products

Car Radiator Machines Car AC Condenser Machines Car AC Evaporator Machines Copper Radiator Machines Intercooler Machines Oil Cooler Machines Home AC Machines Refrigerator Making Machines Copper Fitting Machines Brazing Agent Machinery Nantong Zhenhuan Trade Co., Ltd. Add: No.243,Ninghai Road, Rugao City, Jiangsu Province, China 226500